We are creative people

Nine Years Focusing on Kevlar Aramid Fiber.

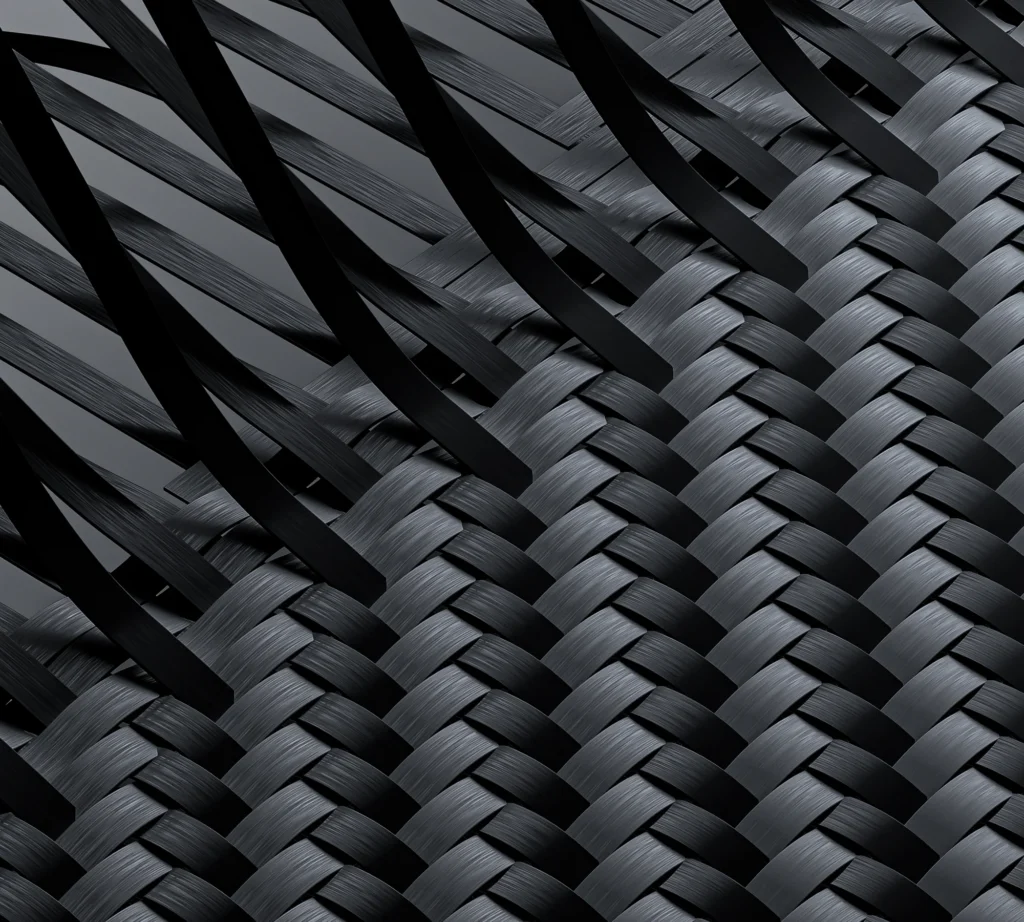

We are committed to continuous innovation, striving to enhance Kevlar aramid fiber material weaving techniques and product designs to deliver superior products to our customers.

Customized Kevlar Aramid Fiber Cases

About us

Trends History

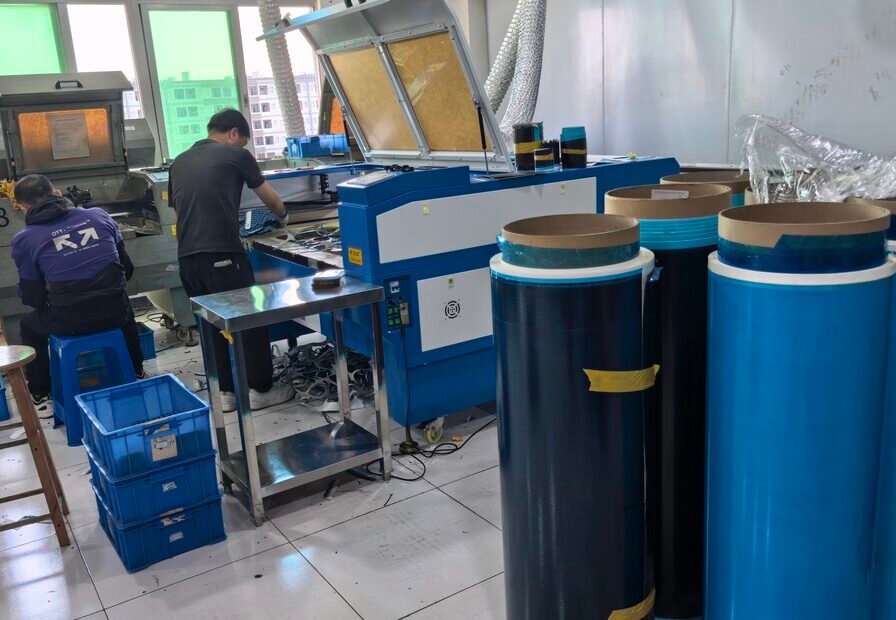

Trends was established in 2016 and currently employs over 100 people, covering an area of 5,000 square meters, with modern workshops and advanced equipment.

The company primarily produces 3C digital products made from DuPont Kevlar aramid fiber, such as mobile phone/Tablet cases, Airpods cases, phone ring stands, and cases on other products’ surfaces.

Our super factory boasts professional production equipment and a dedicated R&D team. It features 20 laser machines, 2 hot press autoclaves, 5 assembly lines, and 2 packaging lines. We ensure superior product quality at every stage, from incoming materials, cutting, wrapping, autoclave molding, polishing, and spraying to final shipment. We offer comprehensive one-stop ODM and OEM manufacturing services, from design and development to production.

OUR ACHIEVEMENT

What We Get

Driven by innovation, we continuously work to refine Kevlar material weaving techniques and product designs, ultimately providing our customers with premium products. We have successfully partnered with many mobile phone accessory brands, enabling them to grow from startup to annual protective case sales of over USD 170 million within one year.

Annual Sales Volume

Market Share

OUR Strength

Trends has a comprehensive solution for customized kevlar aramid fiber, covering a variety of weaving patterns and phone models

Customized Weaving Patterns

We are able to provide tailored product solutions according to customer requirements.

Customized Models

Beyond manufacturing Kevlar protective cases for phones, tablets, and laptops, we offer custom Kevlar casings for a variety of other devices, including Airpods, wireless chargers, power banks, phone stands, and magnetic wallets.

Building Long-Lasting and Stable Relationship

We will share the latest Kevlar raw material market updates with our clients to help them plan their market strategy. What’s more, we will provide reliable after-sales service to our clients.

Flexible MOQ

We offer flexible MOQs to reduce inventory pressure and support our clients’ market growth, ensuring a win-win outcome.

High Quality Standard

There are 20 professional workers as a team in the QA system who gets strictly trained, every process will be strictly inspected to assure the quality。

Consistent Quality and Durability.

We have established long-term partnerships with premium Kevlar material suppliers, such as Dupont, ensuring consistent product quality and reliability.

D, short for Denier, indicates the linear density of the aramid yarn. Fabrics with a low denier are counted to be soft and silky but more difficult to weave. Compared with 1500D aramid fiber, 600D aramid fiber is softer but more difficult to work with. That’s why it’s a rarer material.

Aramid fiber is a generic term for a family of synthetic fibers celebrated for their high strength-to-weight ratio and excellent heat resistance. These properties stem from their unique molecular structure, which consists of long chains of aromatic polyamide units.

Its mechanical properties are better than steel and glass fibers on equal weight. For this reason, aramid fiber has been widely used in aerospace, automotive, and industrial textiles settings.

We take flexible MOQ policy to support our clients, if you have the purchasing plan, please contact us for more details.

Yes, we have the kevlar cases for some mobile phones in stock, please contact us for the stock list.

Sure, we have the powerful R&D team, and we could provide the weaving pattern sample for your reference according to your design. It usually takes 7 ~10 days.

For our current weaving pattern, the lead time is usually 15 days. If you have customized demands, the lead time will be around 30 days after the sample is confirmed.